Tires Recycled Perfectly!

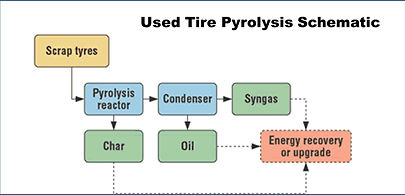

Recycling by Pyrolysis:

Pyrolysis-the thermal degradation in the absence of oxygen- is another way to reprocess scrap tires that is getting increased interest. The byproducts are fuel gas, oils, and a solid residue (char), which contains appreciable quantities of mineral matter and low grade carbon black. The three products have comparable yields by weight.

The two most important factors affecting process economics are the tipping fees charged for tire disposal and the selling prices of the products. Tipping fees have been steadily increasing over years, and this trend is expected to continue. Depending on the region, fees vary from $35 to $108 per ton of whole tires delivered in mass quantities. Selling prices of the products yield low returns because of the low market value of the fuels and the low quality of the recovered char or carbon black (carbon black extracted from the pyrolysis char is of very low purity and cannot be used in tire manufacturing). Therefore, to obtain a positive cash flow, it would be desirable to develop a process based on the recovery of value chemical (e.g. benzene, toluene, and xylene). We believe that significant improvement in the economics can be accomplished by upgrading the primary pyrolysis products to secondary products of higher value.

This is the process what we will utilize in our Tire Recycling efforts. It results in good profit margins and the downsides of fuel cost, etc. can be easily mitigated.